What Is Metrology in 3D Printing?

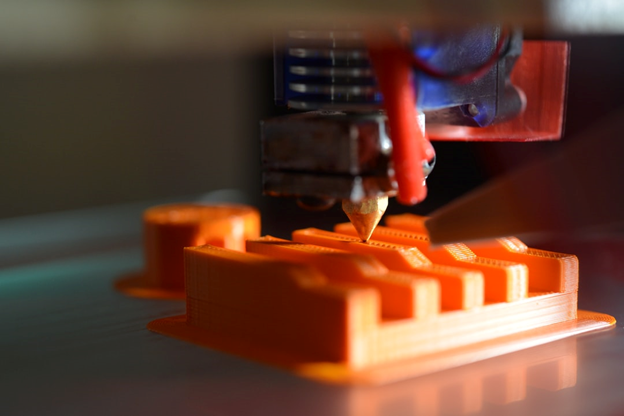

In 2021, the demand for industrial 3D printers rose by 39%. 3D Printing is a dynamic technology that has driven forward over the years, making everyday items, revolutionary medical technologies to humanity-saving tools for the construction industry.

In any industry, the quality assurance process must be excellent. As 3D Printing becomes more popular and expands, so does the need for metrology. But what is metrology in 3D Printing, and how do all the elements work together to make 3D Printing the operational success it is today?

Read on to learn more about metrology for your 3D Printing!

What is Metrology?

Metrology is the science of measurement and is helpful in various fields, including 3D Printing. In 3D Printing, metrology ensures that printed objects have accuracy.

It measures the dimensions of objects and compares them to the desired dimensions. If the things are not the right size, metrology can adjust the printer settings so that they are. Metrology is also used to inspect objects for defects and to ensure that they meet the quality standards.

Different Types of Metrology

There are different types of metrology, each with its advantages and disadvantages. For example, optical metrology is usually more accurate than X-ray metrology but is also more expensive. Here are some of the things you need to know:

Optical Metrology

This process uses lasers and light-based measurement systems to inspect parts. Optical metrology is a non-contact method that is fast and repeatable. It makes it an ideal choice for measuring 3D printed parts.

X-Ray Metrology

X-ray metrology is a type of 3D Printing that uses X-rays to create 3D models and is also known as computed tomography (CT) or X-ray computed tomography (XCT). XCT uses a computer to generate a 3D image from a series of 2D X-ray images. You can use this image to create a 3D model of an object.

X-ray metrology is a powerful tool often used for measuring things that are too complex or too small for other methods. X-ray metrology can create models of objects with intricate features, such as minor components in electronic devices.

Ultrasonic Metrology

Ultrasonic metrology is a type of metrology that uses sound waves to measure the dimensions of objects. It is often used to measure the thickness of materials, such as sheets of metal or plastic. Ultrasonic metrology can measure the width of things, such as the width of a 3D printed part.

Devices Used in 3D Printing Metrology

Metrology for 3D Printing uses various devices and methods, ranging from simple rulers and calipers to more sophisticated laser scanners and coordinate measuring machines (CMMs). A CMM is a device that can measure the coordinates of a point in space. This information is then used to create a map of the object’s geometry.

With the many equipments used in metrology, getting the right one for your specific needs is essential. Take time to research when choosing metrology 3D scanner guides to find the right equipment.

Ensure Accuracy in Your 3D Printing Process with Metrology

Metrology can control the dimensional accuracy of 3D printed parts. By measuring the print process, engineers can ensure that details are within the tolerances required for their application. Metrology is also used to characterize the 3D printing process to optimize it for different materials and applications.

Suppose you’re still asking what is metrology for specific 3D printing materials. In that case, it’s best to contact an expert at your local 3D printing service bureau.

For more answers to questions that perplex you, check out our blog. We have more articles on the latest topics in technology!